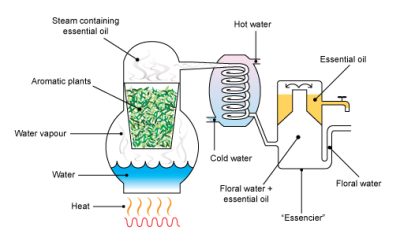

Steam distillation is the process of separating organic compounds or volatile organic compounds (VOCs) from water or water-based process fluids. It is a continuous distillation process particularly useful for removing temperature-sensitive solutes such as natural aromatic compounds.

Steam distillation is a separation technique that harnesses the low boiling point property of immiscible mixtures. It is predominately used to separate temperature-sensitive organic molecules from a non-volatile contaminant. The organic molecule must be immiscible in water.

Garlic Essential Oil

Latin Name: Allium sativum L.

Part Used: Garlic Bulb

Specification: Natural Identical

Appearance: Clear Yellow to Red-orange Oil Liquid

Flavor: Pungent odor and a flavor characteristic of garlic

Active Ingredient: Allicin, Thioether Compound

Refractive Index (20℃): 1.550~1.580

Specific Gravity(20℃): 1.050~1.095

Package: 25KG/50KG Steel-HDPE Bucket

Shelf Life: 24 months

Product Test report.

COA, MSDS, Chemical components analysis report.

Product Certificate.

MUI HALAL, OU KOSHER, BRC, Radiocarbon (C14) Report, ISO22000:2015

Sample for test

Free sample available while shipping cost would be borne by clients

Steam Distillation Extraction Method

Garlic Essential Oil

Garlic essential oil is typically prepared using steam distillation, where crushed garlic is steamed with the resultant condensation containing the oil. Garlic oil contains volatile sulfur compounds such as diallyl disulfide, a 60% constituent of the oil. Steam-distilled garlic oil typically has a pungent and disagreeable odor and a brownish-yellow color. Its odor has been attributed to the presence of diallyl disulfide. To produce around 1 gram of pure steam-distilled garlic oil, around 500 grams of garlic is required. Undiluted garlic oil has 900 times the strength of fresh garlic, and 200 times the strength of dehydrated garlic.

Ether can also be used to extract garlic oil. A type of garlic essential oil involves soaking diced or crushed garlic in vegetable oil, but this is not pure garlic oil; rather it is a garlic-infused oil.

Garlic essential oil is used as a nutritional supplement, and is sometimes marketed in the form of capsules, which may be diluted with other ingredients. Some commercial preparations are produced with various levels of dilution, such as a preparation that contains 10% garlic oil. Herbal folklore holds that garlic oil has antifungal and antibiotic properties, but there is no clinical research confirming such effects. It is also sold in health food stores as a digestive aid.

It can also be used as an insecticide, diluted with water and sprayed on plants.

Stabilized garlic flavor blend is a proprietary mixture of dehydrated garlic powder infused with garlic oil, which increases the flavor of the garlic powder.

Dielegance Biotechnology

![]() Products supplied by Hefei Dielegance Biotechnology Co., Ltd. can be divided into two series, one of which is garlic oil products including Natural Garlic Oil (FCC Grade) and Garlic Essential Oil (Natural Identical), the other of which is ginger oil products including Ginger Oil (Steam Distillation Method) and Ginger Oleoresin (Supercritical CO2 Extraction Method).

Products supplied by Hefei Dielegance Biotechnology Co., Ltd. can be divided into two series, one of which is garlic oil products including Natural Garlic Oil (FCC Grade) and Garlic Essential Oil (Natural Identical), the other of which is ginger oil products including Ginger Oil (Steam Distillation Method) and Ginger Oleoresin (Supercritical CO2 Extraction Method).

Nowadays we get certified with various certification, including GLOBAL G.A.P. Certificate (Registration No. 34019921502323) regarding garlic products

Quality Management System Certificate ISO 9001:2015 (Certificate No.: 00120Q310985R2M/3400)

Food Safety Management System Certificate ISO 22000:2018 (Certificate No.:001FSMS1700533)

MAJELIS ULAMA INDONESIA KETETAPAN HALAL (HALAL DECREE NO.: 00190095060419)

BRC Certificate (Certificate No.: CQC-21-BRC-F-0051), KOSHER (ORTHODOX UNION LETTER OF KOSHER CERTIFICATION),

Cooperative Partner

Two main categories downstream tracing and upstream tracing are conducted in Hefei Dielegance Biotechnology Co., Ltd., including inspection notes, batch numbers, manufacturing and factory data, destination of the product, and how the product is used by consumers.

We have our own raw garlic and ginger plantation base which is certified with GLOBAL G.A.P. to ensure the sufficient raw material supply and adequate stock.

Each production process is visualized in our factory as strict quality control system is implemented during the whole process.

Production capacity for the product is adequate which can meet customers’ requirement as we know how important it is for our business partner.

No matter it is physical or chemical index or even the specific heavy metal and pesticide test and inspection, it can be done by our own professional technical team based on the advanced internal test equipment.

The specific and clear manufacturing flow process can be provided for your side if you need, which makes you have a clear understanding of our production process.

Sample is available for your test before you confirm the product quality and place the order. Besides, each sample quality represents the bulk cargo with same batch number.

Don't see the answer to your question? Ask the project creator directly.